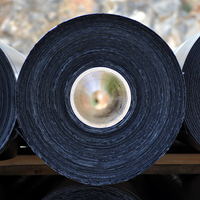

Geomembranes

Geomembranes

Our geomembranes provide high-performance containment solutions for environmental and industrial projects. They are ideal for applications such as landfills, ponds, and agricultural water storage. HITEC is recognized as an experienced manufacturer with outstanding quality and reliable service. Our range includes LLDPE, EVA, FPP and FPE membranes and liners. Our membranes comply with international specifications, such as GRI GM 13. Every lot is submitted to rigorous testing at our state-of-the-art laboratories, during and after production, according to international standards (NSF, ASTM etc). Such controls include density, melt flow index and carbon-black content of the raw-materials, thickness, tensile strength, elongation, impact strength, tear resistance, puncture resistance, modulus of elasticity, ESCR, dimensional stability, oxidative induction time and carbon-black content and dispersion of the membranes.

LLDPE geomembranes are softer and more flexible than HDPE. They do not contain plasticizers and can exhibit excellent UV resistance. They can be produced at larger widths which makes installation faster and more economic.

Advantages

- Flexibility

- Multiaxial stress resistance

- Puncture resistance (in large scale hydrostatic puncture)

- Elongational properties (both uniaxial and multiaxial

- Flexible and soft without using plasticizing additives

Applications

- Tunnels

- Tank liners

- Sewage processing ponds

- Sites with either coarse or soft subgrades

FPP geomembranes are manufactured from a resin which is a reactor alloy of ethylene–propylene rubber particles dispersed on a molecular level in a polypropylene matrix.

Advantages

- Does not require plasticizers

- Factory fabrication of large panels

- Outstanding resistance to ESC

- FPP has excellent low-temperature properties.

- Formability to soil movements

- High friction angle

- Intrinsically flexible

- High resistance in weathering/UV, chemical, puncture, tear, abrasion and cold weather.

- Excellent dimensional stability

- Can be patched using a heat gun

Applications

- Biogas plants

- Water reservoirs

- Fish hatcheries

Aquaculture ponds - Decorative pond liners

- Canal liners

This material has the highest flexibility of all polyolefin liners and is often preferred as replacement of PVC membranes in pond-lining and metal tank lining. Its softening point is lower to that of LLDPE and LDPE, so it is not recommended to use it uncovered in warm climates

Advantages

- Excellent anti permeability

- High puncture resistance

- High barrier properties

- Good flexibility

- Aging resistance

- Chemical corrosion resistance

- Easy welding

Applications

- Roofing – Green roofs

- Aquaculture

- Metal tank lining

- Drainage

- Highway

FPE membranes are designed to offer outstanding chemical resistance and weldability, ensuring a secure and impervious barrier against contaminants and liquids.

Advantages

- Very good mechanical properties,

- Excellent ESCR, flexibility superior to polyethylene,

- Excellent weldability and reparability,

- Lighter weight

- Very low coefficient of linear thermal expansion

- Higher friction coefficient permitting stabilization of soil at a steeper angle.